We’re pleased to feature this week’s guest blogger, Ron Vandermeulen. Ron is an independent expert with over 34 years of saw manufacturing experience.

So, let’s talk saw accuracy. I am not referring to saw cutting accuracy, but rather the tolerance and specifications of the saw.

An accurate saw does not guarantee an accurate cut, but it will prevent inaccuracy. The most important thing to have is a flat, straight saw body. Without this, nothing else matters. The plate tolerance on a guided edger is usually +0.000” to -0.001”. Some manufacturers say their tolerance is -0.0005”, but I have found this is only common for the smaller sizes. If you want that accuracy on the larger diameters there is often an extra cost. You should be randomly checking to ensure that the manufacturers are keeping to their specifications and producing what they committed to.

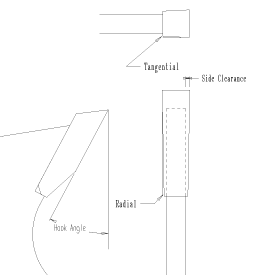

Kerf tolerance is the edge-to-edge tolerance of the width of the saw blade. Carbide tips are usually produced with a kerf tolerance of +0.002” to 0.001”. So, if your kerf is 0.130” it could range from 0.132” down to 0.129”. Side clearance can range 0.002”, so if your side clearance is 0.02” per side than it can range from .019” to 0.021” or 0.018” to 0.020”. This is where the plate thickness can affect the side clearance rather than the kerf. Usually one side remains still while the other side fluctuates. This is caused during the grinding process when the fixed side of the clamping will stay still (unless you have an old machine with weak clamping) while the other side will change according to the variances in plate thickness.

Top grind back clearances and hook angles are +/- 1 degree to what was requested. Radial (top to bottom of tip) clearances should be within 0.002” of each other and tangential (front to back of tip) should be within 0.001”. The total clearance is usually based on many factors like the type of species cut and total clearance to plate. Some mills will reduce these clearances so they do not have to re-tip and in turn, they can get more sharpening from the blade. This is not always advisable because it can sacrifice the quality of the cut.

Spline eyes are trickier depending on the type of arbor you are running. Almost all mills have no way to check the spline eyes other than how the saw feels on the arbor. Over the years there have been a butchering of tolerances by how and who manufactured the arbors. To get a better fit does not mean to just reduce or increase the eye on the saw or arbor. How the blade and arbor contact each other needs to be taken into account.

Take all of these tolerances into consideration to determine how accurate your saw is before making a cut.

Author: Ron Vandermeulen

Phone: 705-752-4245

Email: rvan@outlook.com

Do you want the next article delivered to your Inbox? Subscribe here for ideas and tips on getting the most out of your mill.