For many years saw guides were always made of steel. Steel was the material of choice because it was believed to be the strongest and most economical material.

Since steel is magnetic, it can be put on a surface grinder and ground to very precise tolerances. The Weyerhaeuser Tech Centre maintained that +/- 0.0002” was the accuracy needed to minimize fibre waste during the cutting process (now addressed as ‘recovery’). Because many Weyerhaeuser suppliers could not meet this tolerance, they decided to manufacture their own sawguides.

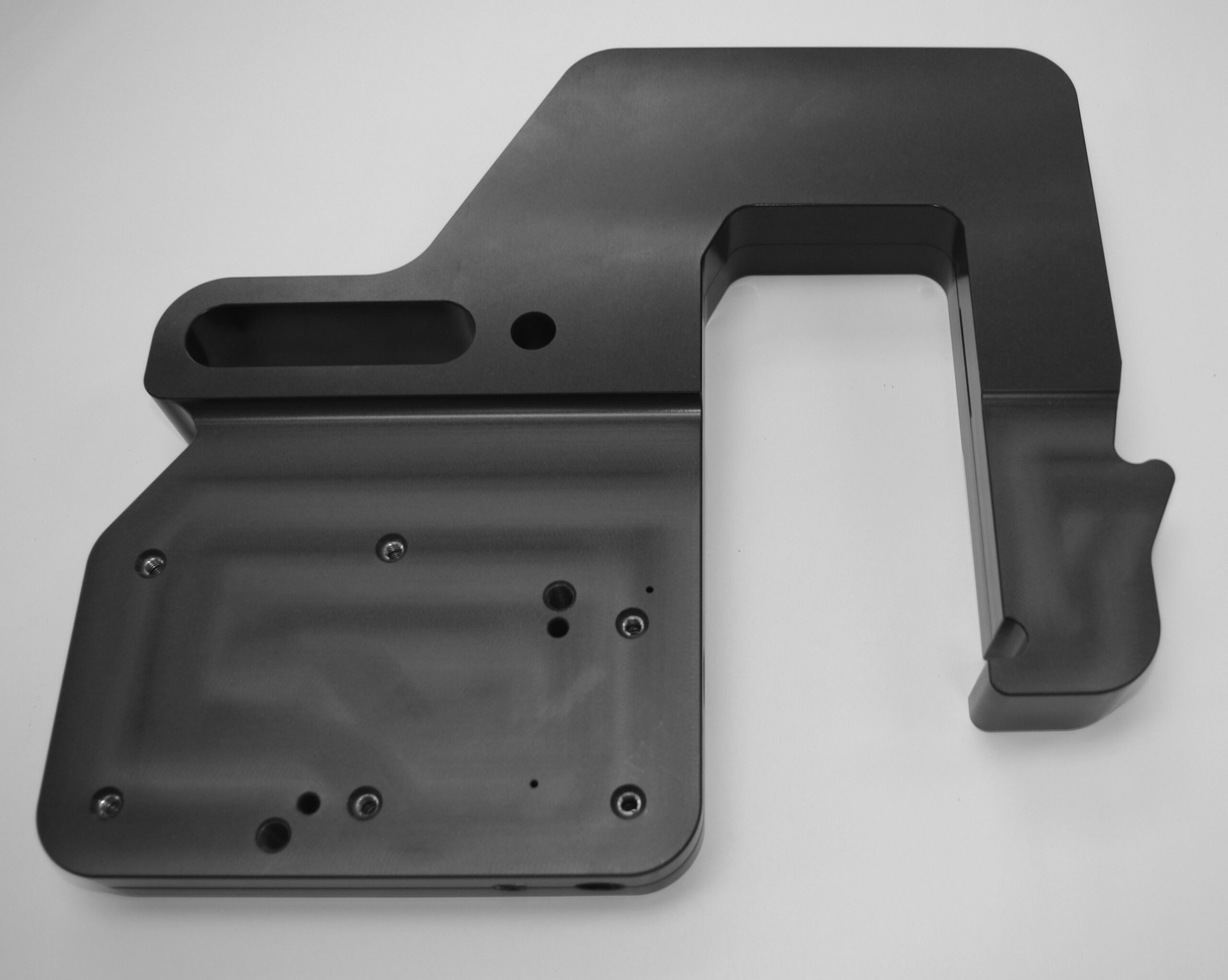

Steel sawguides are very heavy, which can make it difficult to install in sawmill edgers. And injuries due to lifting are very common and very costly to a sawmill. Companies like Weyerhaeuser decided to shift from steel saw guides to aluminum, as aluminum is lighter, and therefore decreased the amount of injuries. Aluminum saw guides do not last as long as steel ones, but the savings resulting from the decrease in injuries is well worth the trade-off.

Even with the move to aluminum saw guides, Weyerhaeuser wanted to maintain a high level of accuracy. This was difficult since aluminum cannot be ground like steel. Weyerhaeuser, however, came up with a proprietary process to achieve this accuracy.

Modern Engineering had been making steel sawguides for many years, always grinding them to accuracy within +/- 0.0002” as demanded by our customers. When customers began asking for aluminum sawguides, it was time to come up with our own process to achieve the highest level of accuracy. We developed our own proprietary honing and polishing technique that allows us to manufacture aluminum sawguides with +/- 0.0002” accuracy. To confirm this accuracy, Modern measures each sawguide with highly accurate Zeiss CNC Coordinate Measuring Machines (CMM’s).

Modern Engineering’s Aluminum Sawguides have become the most accurate in the industry. Our customers have been able to achieve better target size reductions, which reduces wood waste, as well as downtime reductions due to saw guide related issues.

At the heart of every manufacturing business, including ours, is the micrometer—a precision measuring instrument. We believe that saw guides are the micrometer of a sawmill. Running with the most accurate and lightest sawguide will save your mill money in three ways: you will produce more accurate lumber (higher target size reductions than other sawguides), reduce injury related expenses, and you’ll have less downtime.

Generally speaking, all new saw guides will save you money, but only Modern’s Aluminum Saw Guides will take your mill to an entirely new level of cost-saving efficiency—and that’s the reason Modern Engineering hones Aluminum Sawguides.

Author: Udo Jahn